Ürün uygulaması

1500mm x3000mm çalışma alanı ile F3015, ACCURL3015 için temel ve en ekonomik modeldir. Reklam panosu, metal plaka yapısı, Hv/lv elektrik ark üretimi, tekstil makine parçaları, mutfak eşyaları, araba, makine, asansör, elektrikli parçalar, yaylı bobin dilimi, metro hattı yedek parçaları vb.

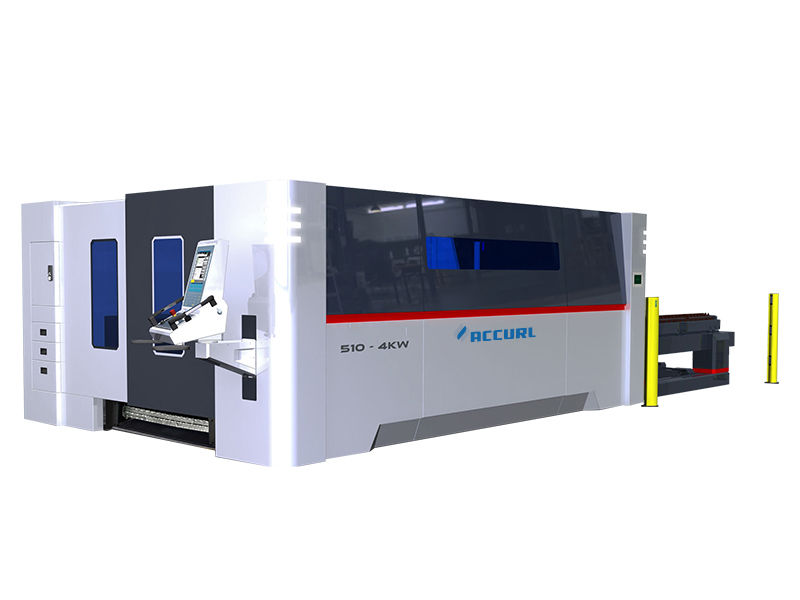

ACCURL3015 İÇİN ÖZELLİKLER FİBER LAZER METAL KESİM MAKİNASI | |||

Lazer kafası | BodorGenius Otomatik Odaklama Lazer Kafası | ||

Lazer kaynağı | IPG/Maksfotonik | ||

Çalışma alanı | 1500 x 3000mm | ||

Lazer gücü | 500w/700w/800w/1000w/1500w/2000w/2500w/3000w/4000w | ||

Soğutma yolu | Su soğutma | ||

Kontrol sistemi | BodorPro | ||

Maksimum Kesme Hızı | 35m / dakika | ||

Hassas | Konum Doğruluğu: 0.03mm. Yeniden Konumlandırma Doğruluğu: 0.02mm | ||

Sürüş sistemi | Japonya YASKAWA Servo Motor | ||

transmisyon | Tayvan gümüş HIWIN kare ray, Tayvan YYC dişli raf | ||

Rulman | Japonya NSK Rulman | ||

Elektrik bileşenleri | Fransız Schneider elektrik bileşenleri | ||

Pnömatik bileşenler | Japonya SMC pnömatik komponentleri | ||

Makine boyutu + ağırlık | 4550*2300*2000mm, Paketten sonra, ağırlık 3000kg | ||

Maksimum hızlanma | 1.5G | ||

Diğer bölümler | Otomatik yağlama sistemi + basınç göstergesi + lazer koruyucu gözlük + WIFI Kontrol + kontrol paneli vb. | ||

Ana Özellikler

1. Mükemmel Yol Kalitesi: Küçük lazer nokta ve yüksek iş verimliliği, yüksek kalite.

2. Yüksek Kesme Hızı: kesme hızı aynı güç CO2 lazer kesme makinesinden 2-3 kat daha fazladır.

3. Kararlı Koşu: üst dünya ithalat fiber lazerleri, istikrarlı performans benimsemek, anahtar parçalar 100.000 saate ulaşabilir;

Fotoelektrik dönüşüm için 4. Yüksek Verimlilik: CO2 lazer kesme makinesi ile karşılaştırın, fiber lazer kesim makinesi üç kez fotoelektrik dönüşüm verimliliği var.

5. Düşük Maliyet: Enerjiden tasarruf edin ve çevreyi koruyun. Fotoelektrik dönüşüm oranı% 25-30'a kadardır. Düşük elektrik tüketimi, geleneksel CO2 lazer kesim makinesinin sadece% 20-30'u kadardır.

6. Düşük Bakım: fiber hat iletimine ihtiyaç duymadan lensi yansıtır, bakım maliyetini azaltır;

7. Kolay İşlemler: Fiber hat iletimi, optik yolun ayarlanması yok.

Hızlı Ayrıntılar

Durum: Yeni

Lazer Tipi: Fiber Lazer

Uygulanabilir Malzeme: Metal

Kesme Kalınlığı: bağlıdır

Kesim Alanı: 1500x3000mm

Kesme Hızı: 500mm/s

CNC veya Değil: Evet

Soğutma modu: su soğutma

Kontrol Yazılımı: BodorPro

Desteklenen Grafik Formatı: AI, BMP, DXF, PLT

Sertifika: CCC, CE, ISO, SGS, UL

Sağlanan Satış Sonrası Hizmet: Yurtdışı hizmet amaçlı kullanılabilir makine mühendisleri

Anahtar kelime: sıcak satış metal lazer kesim makinesi

Kesme kalınlığı: 0-30mm

Konum doğruluğu: 0,02 mm

Kesme hızı: 0-10000mm/dak

Kesme malzemesi: Metal paslanmaz çelik karbon çelik alüminyum

Uygulama: Alüminyum Levhalar

Mengene eylem Yöntemi: Yarı Otomatik Sıkma Mengenesi

Güç: Mekanik

marka: bodor

endüstri: mücevher metal ürünleri otomobil parçaları

Makine parçaları

Adı: BodorGenius Otomatik Odaklı Lazer Kafası

1, Otomatik Odaklama

Takım tezgahı kontrol sistemi tarafından kontrol edilen çeşitli odak uzunluklarına uygulanabilir. Farklı kalınlıktaki levha metallerin en iyi kesim etkisini elde etmek için, kesme işleminde odak noktası otomatik olarak ayarlanacaktır.

2, Ellerinizi Serbest Bırakın

Odak uzaklığı işletim sistemi tarafından kontrol edilir. Manuel işlemden kaynaklanan hataları veya arızaları etkili bir şekilde önleyen manuel düzenleme yapmamıza gerek yoktur.

3, Hızlı

(1) Otomatik odaklama, kesme hızını büyük ölçüde artıran delme ve kesme sürecinde en uygun odak noktalarını otomatik olarak ayarlar;

(2) Farklı malzemeleri veya farklı kalınlıktaki levhaları değiştirirken, manuel odaklı lazer kafası, zahmetli ve zaman alıcı olan manuel düzenlemeye ihtiyaç duyar; otomatik odaklama lazer kafası kontrol sistemi tarafından kontrol edilir, sistem depolama parametrelerini otomatik olarak okuyabilir, zamandan ve insan gücünden tasarruf sağlar;

(3) Kolimatör koruyucu lens çekmecesi, kolimatör lensi daha iyi koruyabilir ve koruyucu lensin değiştirme hızını iyileştirebilir.

4, Doğruluk

Perforasyon odak uzunluğunu artırmak, perforasyon odak uzunluğunu ayrı ayrı ayarlamak ve odak uzunluğunu ayarlamak, kesim hassasiyetini arttırır.

5, Dayanıklı

(1) Dahili çift su soğutma yapıları, lenslerin aşırı ısınma hasarını önleyerek, kolimasyon ve odaklama bileşenlerinin sabit sıcaklığını sağlayabilir, soğutma etkisi daha iyidir, uzun süreli kesimde ısıtma veya buğulanma olmaz, lenslerin servis ömrü uzar.

(2) Artan kolimasyon koruyucu lens ve odak koruyucu lens, ana bileşenleri dikkatlice koruyun.

Adı: Entegre Döküm Makinesi Gövdesi

En düşük gerilme mukavemeti 200MPa olan pul grafit dökme demir kullanarak. Yüksek karbon içeriği, yüksek basınç dayanımı ve yüksek sertlik. Güçlü şok emilimi ve aşınma direnci. Düşük termal hassasiyet ve yatak aralığı hassasiyeti, kullanım sırasında ekipman kaybını azaltır, böylece makine hassasiyeti uzun süre korunabilir ve yaşam döngüsünde herhangi bir deformasyon olmaz.

Adı: Kontrol kabini

Lazer kaynağını ve tüm elektronik makine parçalarını entegre eden kabin, değerli elektrikli parçaları ve pahalı lazer kaynağını koruyabilir. Kabin içindeki fan, elektrikli parçalar için daha iyi bir soğutma sistemi sağlar.

Adı: Otomatik yağlama sistemi

Elektrikli yağlama, rasyonel yapıya, mükemmel performansa ve kapsamlı işlevlere sahip bir tür dişli pompadır.

Ana makinedeki program kontrol sistemi ile bağlantı kurarak, yağlama sistemi, tank içindeki yağ seviyesini ve ayrıca yağ iletim basıncını denetleyebilir ve yağlama sistemi içinde paslanmayı etkili bir şekilde önleyecek olan yağlama periyodunu ayarlayabilir, bu da kesim doğruluğunu sağlamak için.